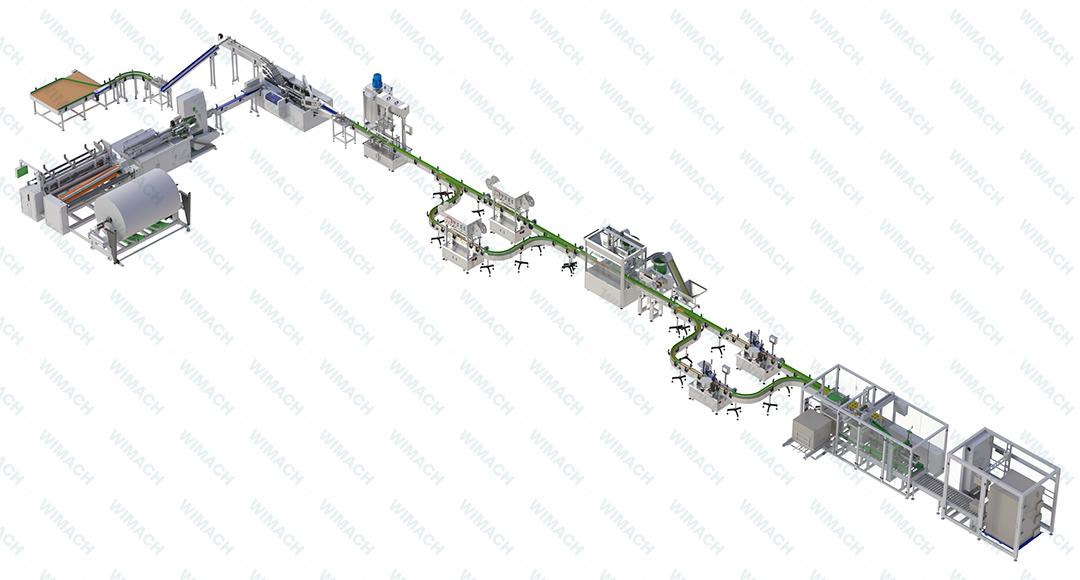

Canister Wet Wipe Production and Packaging Line

Description

Canister wet wipe production and packaging line is designed to produce wet wipes and pack wipes with canisters automatically. This is a turnkey solution for wet wipes.

The production capacity is up to 60 CPM. The canister wet wipe line can be customized accroding customer's requirements.

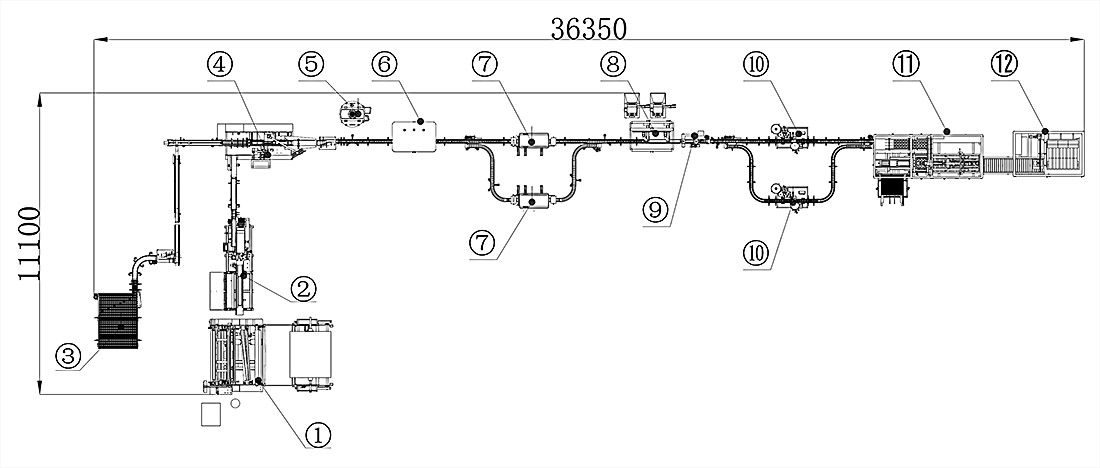

The production line mainly consist of following units:

1) Rewinding machine: rewind wipe rolls from parent roll;

2) Slitting machine: slit wipe rolls into small rolls;

3) Canister unscrambler: collating canisters and feed them on the wipe stuffing machine;

4) Wipe tissue roll stuffing machine: stuffe small wipe rolls into canisters;

5) Stainless steel tank;

6) Multi-head Filling machine: fill alcohol into canisters;

7) Canister sealing machine: seal canisters with aluminum foil;

8) Mobile canister capping machine: feed caps and seal caps with canisters;

9) Caps pressing machine;

10) Canister labeling machine: stick labels around canisters;

11) Automatic case packer: put canisters into cartons;

12) Palletizer: stack cartons on pallets.

Video

Layout of the Canister Wet Wipe Production and Packaging Line